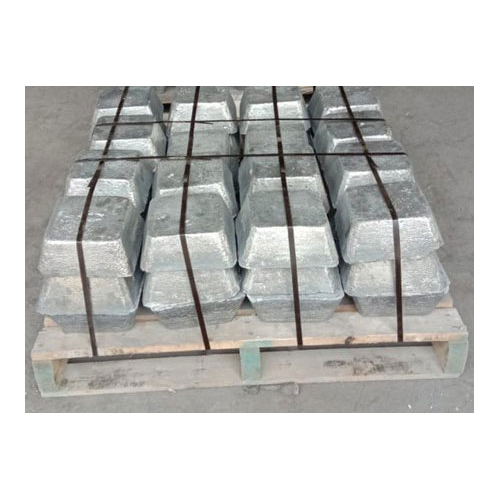

Antimony Metal Ingots

Product Details:

- Product Type Metal Products

- Material Alloy

- Shape Rectangle

- Density 6.684 Gram per cubic centimeter(g/cm3)

- Weight 24 Kilograms (kg)

- Color Grey

- Click to View more

Antimony Metal Ingots Price And Quantity

- 500 Metric Ton

Antimony Metal Ingots Product Specifications

- 6.684 Gram per cubic centimeter(g/cm3)

- 24 Kilograms (kg)

- Grey

- Alloy

- Metal Products

- Rectangle

Antimony Metal Ingots Trade Information

- CIF

- Others

- 1000 Metric Ton Per Day

- 1 Week

- Wooden Pallet

- Australia, Central America, North America, Eastern Europe, Middle East, Western Europe, Africa, South America, Asia

Product Description

The high density antimony metal ingots are highly resistant to corrosion and erosive substances. If you belong to rubber, paint, electronic, ceramic or any other industry, who requires silvery antimony ingots in the process must contact us. Our company can supply toughand high strength ingots that can be easily welded or malleated. We supply two grades: regular grade and high grade of antimony metal ingots.

Applications of Antimony Metal Ingots

- Principally in alloys with lead for storage battery grids.

- For alloys which expand on solidification and for solders.

- In alloys with other metals for electrical & other uses and for manufacturing Antimony Compounds.

- Also used in lead Acid Batteries.

- Metal Ingot Size : 20 kgs- 24 kgs

- Packing : One Ton on Wooden Pallet with Stretch Wrap.

- For manufacturing Antimony Compounds

- In the form of antimony black as bronzing coating for metals and plaster casts

- For alloys which expand on solidification

- For solders

- Principally in alloys with lead for storage battery grids

- In alloys with other metals for electrical & other uses

Product Details :

- Minimum Order Quantity :50000 Kg

- Metal Ingot Size :20 kgs- 24 kgs

- Packing :One Ton on Wooden Pallet with Stretch Wrap.

- Density :6.684 g/cm3.

- Melting Point :630.74 Degree C.

- Shape :INGOT

- Color :grey

Technical Specification of Antimony Metal Ingots

|

Properties |

Regular Grade |

High Grade |

|

Antimony (Sb) |

99.65% Min. |

99.85%Min. |

|

Arsenic (As) |

0.10% Max. |

0.02% Max. |

|

Lead (Pb) |

0.20% Max. |

0.10% Max. |

|

Iron (Fe) |

0.01% Max. |

0.01% Max. |

|

Copper (Cu) |

0.01% Max. |

0.01% Max. |

|

(Se) |

50 PPM Max. |

10PPM Max. |

|

(Bi) |

100ppm Max. |

50PPM Max. |

Exceptional Material Properties

With a robust density of 6.684 g/cm3 and substantial weight of 24 kg per ingot, Antimony Metal Ingots offer strength and durability. The rectangular shape ensures ease of handling during transportation and processing, while the alloy composition extends their application across multiple industries.

Reliable Sourcing from India

Our Antimony Metal Ingots are supplied directly from trusted exporters, manufacturers, and wholesalers based in India. Customers benefit from high standards of quality control, reliable availability, and tailored solutions for various bulk and small-scale requirements.

FAQs of Antimony Metal Ingots:

Q: How are Antimony Metal Ingots typically used in industries?

A: Antimony Metal Ingots are primarily used in metallurgy as a hardening agent for lead and other alloys, and in the electronics industry for producing semiconductors. They are also commonly utilized in manufacturing flame retardants and specific batteries.Q: What process is involved in the production of these ingots?

A: The production involves refining antimony ore or recycled material, melting it in controlled conditions, and casting it into rectangular molds to achieve the specified density and weight. Quality checks ensure consistency in shape, purity, and alloy composition.Q: Where are these Antimony Metal Ingots sourced from?

A: These ingots are available from exporters, manufacturers, suppliers, and wholesalers based in India, known for their stringent quality measures and reliable supply channels.Q: What are the benefits of choosing alloy-based Antimony Metal Ingots?

A: Alloy-based Antimony Metal Ingots provide enhanced strength, improved thermal stability, and greater resistance to corrosion, making them suitable for demanding industrial processes and long-term usage.Q: When should businesses consider using Antimony Metal Ingots?

A: Businesses should use Antimony Metal Ingots when they require durable materials for alloying, flame retardant production, or electronics manufacturing. Their reliable quality and consistency make them suitable for both small and large-scale industrial operations.Q: What shapes and sizes are available for these ingots?

A: These Antimony Metal Ingots are produced in rectangular shapes with a standard weight of 24 kilograms per ingot, facilitating easy stacking, handling, and integration into various production processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

CHEMICO SYNTHETICS LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS